In fluid and gas systems, threaded fittings play a vital role in ensuring secure, leak-free connections between pipes, hoses, and components. These threads determine how well two fittings connect and seal under pressure, making them essential in maintaining system reliability and safety.

Among the various thread standards used globally, BSP (British Standard Pipe) and NPT (National Pipe Tapered) stand out as the two most widely recognized. Both are designed for creating reliable joints in hydraulic, pneumatic, and plumbing systems, but they differ in design, origin, and application.

This article provides a quick technical overview of the difference between BSP and NPT threads, helping you understand their unique characteristics and choose the correct type for your system.

What Are Thread Standards?

A thread standard defines the dimensions, angle, pitch, and form of the threads used on pipes and fittings. In simple terms, it’s the rulebook that ensures two threaded components fit together properly.

Thread standards play a crucial role in:

➡️ Ensuring compatibility between fittings from different manufacturers.

➡️ Maintaining sealing performance under pressure.

➡️ Preventing leakage or mechanical failure in hydraulic and pneumatic systems.

Globally, the BSP and NPT thread standards dominate most industrial applications, especially in hydraulics, pneumatics, oil & gas, and plumbing. Understanding how they differ is key to system performance and safety.

Overview of BSP Threads

BSP stands for British Standard Pipe, a thread type that originated in the United Kingdom and is now commonly used across Europe, Asia, Australia, and parts of Africa.

Subtypes of BSP Threads

1. BSPP (British Standard Pipe Parallel) – Features parallel (straight) threads. Sealing is typically achieved using an O-ring, washer, or bonded seal at the face of the fitting.

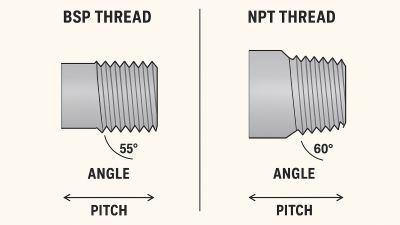

2. BSPT (British Standard Pipe Tapered) – Has a tapered thread form similar to NPT, but with a 55° thread angle instead of 60°. Sealing occurs through thread interference and the use of sealants.

Key Design Characteristics

➡️ Thread angle: 55° Whitworth form.

➡️ Sealing method: Mechanical seal using a washer (BSPP) or thread sealant (BSPT).

➡️ Profile: Rounded crests and roots for smoother sealing surfaces.

➡️ Measurement standard: Metric.

Common Applications

BSP threads are widely used in:

➡️ Hydraulic and pneumatic systems.

➡️ Industrial machinery.

➡️ Water, gas, and air fittings in regions following British or ISO standards.

Overview of NPT Threads

NPT stands for National Pipe Tapered, a thread standard developed in the United States and predominantly used across North America.

Thread Design Features

➡️ Thread angle: 60°.

➡️ Form: Tapered—meaning the diameter decreases along the thread length, enabling a tight, interference-based seal.

➡️ Sealing method: Relies on the metal-to-metal contact created by the taper, usually enhanced with thread sealant or PTFE tape.

Typical Applications

NPT threads are commonly found in:

➡️ Hydraulic and pneumatic systems.

➡️ Oil and gas pipelines.

➡️ Water and air distribution systems.

➡️ Plumbing and industrial equipment made for North American markets.

Key Technical Differences Between BSP & NPT Threads

|

Feature |

BSP Threads |

NPT Threads |

|

Full Form |

British Standard Pipe |

National Pipe Tapered |

|

Thread Angle |

55° |

60° |

|

Thread Type |

Parallel (BSPP) / Tapered (BSPT) |

Tapered only |

|

Sealing Method |

Uses O-ring or washer (BSPP) or thread sealant (BSPT) |

Seals via thread interference |

|

Measurement Standard |

Metric |

Imperial |

|

Common Regions |

UK, EU, Asia, Australia |

USA, Canada, North America |

NPT vs BSP: Industry Standards Compared

Compatibility Issues Between BSP & NPT Threads

Although BSP and NPT fittings may appear similar at first glance, they are not interchangeable due to critical differences in thread form, angle, and pitch.

1. Thread Angle Mismatch: BSP threads have a 55° angle, while NPT threads use 60°. This prevents proper engagement and sealing.

2. Pitch and Diameter Variations: Even small variations in thread pitch or diameter can cause poor fitment.

3. Sealing Differences: BSPP requires a sealing washer, whereas NPT depends on thread interference. Mixing the two can lead to cross-threading, leakage, or mechanical damage.

BSP & NPT Thread Compatibility Chart (Threads Per Inch)

|

Nominal Pipe Size |

BSPP/BSPT (British Standard Pipe) |

NPT (National Pipe Tapered) |

Threads Per Inch (TPI) |

Compatible? |

|

1/16″ |

BSPT: 28 |

NPT: 27 |

27–28 |

❌ Not Compatible |

|

1/8″ |

BSPT: 28 |

NPT: 27 |

27–28 |

❌ Not Compatible |

|

1/4″ |

BSPT: 19 |

NPT: 18 |

18–19 |

❌ Not Compatible |

|

3/8″ |

BSPT: 19 |

NPT: 18 |

18–19 |

❌ Not Compatible |

|

1/2″ |

BSPT: 14 |

NPT: 14 |

14 |

❌ Not Compatible (different angle/profile) |

|

3/4″ |

BSPT: 14 |

NPT: 14 |

14 |

❌ Not Compatible (different thread form) |

|

1″ |

BSPT: 11 |

NPT: 11.5 |

11–11.5 |

❌ Not Compatible |

|

1-1/4″ |

BSPT: 11 |

NPT: 11.5 |

11–11.5 |

❌ Not Compatible |

|

1-1/2″ |

BSPT: 11 |

NPT: 11.5 |

11–11.5 |

❌ Not Compatible |

|

2″ |

BSPT: 11 |

NPT: 11.5 |

11–11.5 |

❌ Not Compatible |

|

2-1/2″ |

BSPT: 11 |

NPT: 8 |

8–11 |

❌ Not Compatible |

|

3″ |

BSPT: 11 |

NPT: 8 |

8–11 |

❌ Not Compatible |

|

4″ |

BSPT: 11 |

NPT: 8 |

8–11 |

❌ Not Compatible |

Notes:

1. Even though some BSP and NPT sizes have similar TPI values, they are not interchangeable due to:

➡️ Different thread angles (BSP = 55°, NPT = 60°).

➡️ Different thread shapes and pitch diameters.

➡️ Different sealing methods (BSPP uses washer/O-ring, NPT uses thread interference).

2. Using mismatched threads can lead to cross-threading, poor sealing, and potential leaks.

3. Always confirm compatibility using a thread gauge or reference chart before installation.

How to Identify BSP vs NPT Threads

For engineers and technicians, proper identification is essential before installation. Here’s how to tell them apart:

1. Check the Thread Angle:

➡️ BSP = 55°

➡️ NPT = 60°

Use a thread gauge or comparator tool.

2. Observe the Sealing Method:

➡️ BSPP fittings usually have a flat sealing face for washers or O-rings.

➡️ NPT fittings rely on the taper for sealing.

3. Measure Thread Pitch and Diameter:

➡️ Use calipers and thread gauges to measure thread spacing accurately.

4. Look for Markings:

➡️ Many fittings are labeled “BSP” or “NPT” on the hex or body for quick identification.

Choosing the Right Thread Type

Selecting the correct thread type depends on several factors:

1. Geography: Systems in Europe and Asia typically use BSP, while North American systems favor NPT.

2. Machinery Origin: Always match fittings to the standard specified by the equipment manufacturer.

3. System Requirements: Consider sealing needs, pressure ratings, and compatibility.

If you need to connect BSP and NPT components, use thread adapters or conversion fittings designed for that purpose. Never force incompatible threads together, it can cause leaks or equipment failure.

Also, when in doubt, consult manufacturer reference charts or fitting specialists for guidance.

Conclusion

Understanding the difference between BSP and NPT threads is crucial for maintaining safe and reliable fluid connections. While both serve the same purpose, their technical differences in thread angle, sealing method, and region of use make them non-interchangeable.

Choosing the right standard prevents leaks, ensures compatibility, and extends the life of your equipment.

Looking for reliable BSP or NPT fittings? Explore our high-quality range of hydraulic connectors and adapters designed to meet international standards and deliver leak-free performance every time.

Post time: Nov-13-2025