Whether you are a DIY enthusiast tackling a leaky sink or an engineer designing an industrial fluid system, you have likely encountered the compression valve fitting. These mechanical marvels are the unsung heroes of plumbing, providing a reliable way to join pipes without the need for heat, solder, or complex machinery.

In this guide, we will break down everything you need to know about compression valve fittings, from their internal components to the physics of how they create a leak-proof seal.

What Is a Compression Valve Fitting?

A compression valve fitting is a type of coupling used to connect two pipes or a pipe to a fixture (like a faucet or toilet). Its primary purpose is to create a secure, watertight, and airtight connection using mechanical force.

How They Differ from Other Fittings

➡️ Threaded Fittings: Require the pipe itself to be threaded.

➡️ Welded/Soldered Fittings: Use heat to melt a filler metal to join parts.

➡️ Push-fit Fittings: Rely on internal teeth and O-rings for a “plug-and-play” connection.

➡️ Compression Fittings: Use a “ferrule” that is physically crushed onto the pipe to create a seal.

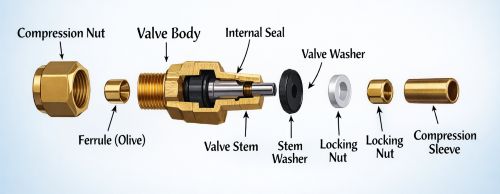

Main Components of a Compression Valve Fitting

A standard compression fitting consists of three primary parts that work in harmony:

1. Compression Nut: This is the outer threaded cap. As you tighten it onto the valve body, it provides the mechanical leverage needed to compress the internal ring.

2. Compression Ring (Ferrule/Olive): A small, barrel-shaped ring (often made of brass or copper). This is the “secret sauce” of the fitting; it sits between the nut and the body.

3. Valve Body: The main housing that contains the fluid flow mechanism. It features external threads to receive the nut and an internal “seat” where the pipe rests.

4. The Pipe: While not part of the fitting itself, the pipe must be rigid enough (copper, PEX with inserts, or steel) to withstand the pressure of the ferrule.

How Does a Compression Valve Fitting Work?

The beauty of a compression fitting lies in its simplicity. Here is the step-by-step physics of the seal:

1. Insertion: The pipe is pushed into the valve body until it hits the internal shoulder.

2. Tightening: As the compression nut is screwed onto the body, it pushes the ferrule forward.

3. Deformation: Because the valve body has a tapered internal seat, the ferrule is squeezed inward as it is pushed.

4. The Seal: The ferrule “bites” into the outer diameter of the pipe, deforming slightly to create a permanent, 360-degree seal that prevents fluid from escaping.

No soldering or welding is required, making this an ideal “cold” connection method for tight spaces or areas where a torch would be a fire hazard.

Types of Compression Valve Fittings

1. Straight Compression Valves: Connects two pipes in a direct line.

2. Angle Compression Valves: Turns the flow 90 degrees (common under sinks).

3. T-shaped Compression Valves: Splits one line into two.

4. Single vs. Double Ferrule: Single-ferrule designs are common in home plumbing, while double-ferrule designs (like Swagelok) are used in high-pressure industrial applications for extra grip.

Common Materials Used

Choosing the right material is vital for longevity:

➡️ Brass: The gold standard for residential water and gas. It is corrosion-resistant and durable.

➡️ Stainless Steel: Used in industrial settings for high-pressure or highly corrosive fluids.

➡️ Plastic/Composite: Common in low-pressure irrigation or specialized chemical applications.

Advantages of Compression Valve Fittings

➡️ Easy Installation: Only basic wrenches are needed.

➡️ Removable: They can be disassembled easily, which is great for maintenance.

➡️ Safety: No flames or toxic flux fumes.

➡️ Versatility: Works on a wide variety of pipe materials.

Typical Applications

1. Residential Plumbing: Water shut-off valves for toilets and faucets.

2. Water Supply Lines: Connecting refrigerators or ice makers.

3. HVAC: Refrigerant lines and oil supply lines for furnaces.

4. Industrial Hydraulics: Controlling fluid flow in machinery.

Installation Tips and Best Practices

To ensure a leak-free life for your fitting, follow these rules:

➡️ Clean Cuts: Use a pipe cutter for a perfectly square end.

➡️ Deburring: Always remove the sharp burrs from the inside and outside of the pipe.

➡️ The “Feel” of Tightness: Tighten the nut finger-tight, then use a wrench for another 1/2 to 3/4 turn.

➡️ Alignment: Ensure the pipe is perfectly straight entering the fitting; if it’s angled, the ferrule won’t seat correctly.

Common Mistakes to Avoid

➡️ Over-tightening: This is the #1 cause of leaks. Over-tightening can crack the nut or “oval” the pipe, ruining the seal.

➡️ Reusing Ferrules: Once a ferrule is compressed, it is permanently deformed. Always use a new ferrule if you disconnect the fitting.

➡️ Thread Sealant: Do not use Teflon tape or pipe dope on the compression threads. The seal happens at the ferrule, not the threads. Tape can actually prevent the nut from tightening fully.

Comparison: Compression vs. Other Methods

|

Feature |

Compression |

Soldered (Sweat) |

Push-Fit (SharkBite) |

|

Skill Level |

Beginner |

Intermediate/Advanced |

Beginner |

|

Tools Needed |

Two Wrenches |

Torch, Solder, Flux |

None |

|

Cost |

Moderate |

Low (Materials) |

High |

|

Permanence |

Removable |

Permanent |

Removable |

Frequently Asked Questions (FAQs)

Can compression valve fittings be reused?

The valve body and nut can be reused, but the ferrule must be replaced every time the connection is broken.

Are they reliable long-term?

Yes. When installed correctly, compression fittings can last decades. However, they are generally not recommended for use inside walls (concealed plumbing) where a leak wouldn’t be visible.

Do they work with plastic pipes?

Yes, but you must use a plastic ferrule and an internal plastic insert (stiffener) to prevent the pipe from collapsing.

Conclusion

Compression valve fittings are a reliable, versatile, and accessible solution for fluid control. By understanding the mechanical relationship between the nut, ferrule, and body, you can create professional-grade connections with nothing more than a pair of wrenches. Just remember: don’t over-tighten, and always prep your pipe!

Post time: Jan-08-2026