Hydraulic systems power many industrial and mobile machines by using pressurized fluid. These systems depend on tubes, hoses, and fittings to move fluid safely and efficiently. Among them, hydraulic fittings are essential for creating strong, leak-free connections.

In high-pressure systems, even small leaks can cause safety risks, downtime, and equipment damage. Hydraulic compression tee fittings help prevent these issues by providing secure connections while allowing fluid flow to split in different directions.

This article explains what a hydraulic compression tee fitting is, how it works, where it is used, its main benefits, and key tips for proper selection and installation.

What Is a Hydraulic Compression Tee Fitting?

A hydraulic compression tee fitting is a type of hydraulic fitting used to connect three sections of tubing in a “T” configuration. It allows fluid flow to be divided or combined within a hydraulic system while maintaining a secure, leak-resistant connection.

The defining feature of a compression tee fitting is its compression-based sealing method. Instead of welding or flaring the tube, the fitting uses mechanical compression to seal the tube against the fitting body. This makes installation easier and allows for disassembly and reuse.

The “tee” configuration refers to the three connection points: one inlet and two outlets (or vice versa). This design enables fluid branching, making compression tee fittings ideal for distributing hydraulic fluid to multiple system components.

Compared to straight compression fittings, which connect two tubes in a straight line, or elbow fittings, which change the direction of flow, tee fittings are specifically designed for flow division. Hydraulic compression tee fittings are available in various standards and designs, including metric and imperial sizes, as well as industry standards such as DIN, ISO, and SAE.

Key Components of a Hydraulic Compression Tee Fitting

Understanding the individual components of a hydraulic compression tee fitting helps explain how it achieves a reliable seal.

Tee Body

The tee body is the main structure of the fitting. It houses the three ports and provides the internal geometry that supports the compression seal. The body is designed to withstand high pressures and mechanical stress.

Compression Nut

The compression nut threads onto the fitting body. When tightened, it applies force to the ferrule(s), driving them into position to create a seal.

Ferrule(s)

Ferrules are small metal rings that form the compression seal. Single ferrule designs use one ring, while double ferrule designs use two rings—typically a front ferrule for sealing and a back ferrule for gripping the tube.

Sealing Surfaces

The sealing surfaces inside the fitting body interact with the ferrules and tubing to create a tight, leak-proof connection.

Materials Used

Hydraulic compression tee fittings are commonly manufactured from carbon steel, stainless steel, or brass. Material selection depends on pressure requirements, fluid compatibility, and environmental conditions.

How Does a Hydraulic Compression Tee Fitting Work?

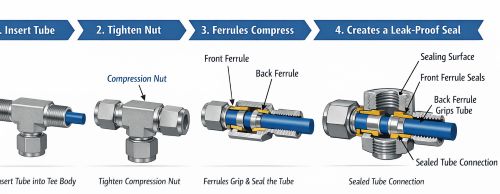

A hydraulic compression tee fitting works by mechanically compressing ferrules onto the outer surface of the tube to create a strong seal.

First, the tube is inserted into the fitting body until it reaches the internal stop. The ferrule(s) and compression nut are positioned over the tube. As the compression nut is tightened, it forces the ferrules forward.

The ferrules deform slightly under pressure, gripping the tube and sealing against the fitting body. This creates a metal-to-metal seal that is highly resistant to leakage. In double ferrule designs, the back ferrule provides a strong tube grip, while the front ferrule forms the primary seal.

This interaction between the tube, ferrules, and fitting body allows the connection to maintain performance even under high pressure and vibration. Proper torque during installation is essential, too little torque can cause leaks, while excessive torque may damage the tube or ferrules.

Types of Hydraulic Compression Tee Fittings

Hydraulic compression tee fittings are available in several configurations to suit different system requirements.

Equal Tee Fittings

All three ports are the same size, allowing equal flow distribution.

Reducing Tee Fittings

One or more ports are smaller, enabling flow reduction or branching to smaller tubing.

Male and Female Threaded Tee Fittings

These designs combine compression connections with threaded ports for integration with other hydraulic components.

Metric vs. Imperial Designs

Fittings are available in metric or inch-based sizes to match tubing standards.

Single Ferrule vs. Double Ferrule Compression Tees

Single ferrule fittings are simpler, while double ferrule fittings offer enhanced sealing and vibration resistance.

Common Applications of Hydraulic Compression Tee Fittings

Hydraulic compression tee fittings are used across a wide range of industries and systems, including:

1. Industrial hydraulic systems in manufacturing plants

2. Mobile equipment and heavy machinery

3. Oil and gas fluid transfer systems

4. Construction and agricultural equipment

5. Hydraulic fluid distribution and branching systems

Their versatility and reliability make them suitable for both stationary and mobile applications.

Advantages of Using Hydraulic Compression Tee Fittings

Hydraulic compression tee fittings offer several key benefits:

➡️ Leak-free, reliable connections

➡️ High resistance to pressure and vibration

➡️ Easy installation without special tools

➡️ Reusability and simplified maintenance

➡️ Excellent compatibility with rigid metal tubing

These advantages make them a preferred choice in many hydraulic systems.

Installation Best Practices

Proper installation is critical to achieving optimal performance.

1. Cut tubing cleanly and squarely

2. Ensure correct tube insertion depth

3. Align the fitting properly before tightening

4. Follow recommended tightening procedures

5. Avoid common mistakes such as misalignment or over-tightening

6. Always follow manufacturer specifications and torque guidelines

Common Problems and How to Prevent Them

Some common issues with hydraulic compression tee fittings include:

1. Leakage caused by improper tightening

2. Tube deformation due to excessive force

3. Incorrect material selection for the application

4. Over-tightening or under-tightening

Regular inspection, proper installation, and correct material selection can help prevent these problems and extend fitting life.

How to Choose the Right Hydraulic Compression Tee Fitting

When selecting a hydraulic compression tee fitting, consider the following factors:

➡️ System pressure and temperature requirements

➡️ Tube size, wall thickness, and material

➡️ Compatibility with hydraulic fluids

➡️ Environmental conditions such as corrosion or vibration

➡️ Compliance with relevant industry standards

Choosing the right fitting ensures long-term system reliability and safety.

Hydraulic Compression Tee Fittings vs. Other Tee Fittings

Compared to welded tee fittings, compression tee fittings offer easier installation and maintenance. Unlike flare tee fittings, they do not require flaring tools. When compared to push-to-connect fittings, compression tees provide superior performance in high-pressure hydraulic environments. Compression tee fittings are ideal when reliability, reusability, and pressure resistance are required.

Frequently Asked Questions (FAQ)

Are hydraulic compression tee fittings reusable?

Yes, most designs are reusable if properly installed and not damaged.

Can they be used in high-vibration environments?

Yes, especially double ferrule designs, which offer improved vibration resistance.

What pressure ratings are typical?

Pressure ratings vary by design and material, but many are suitable for high-pressure hydraulic systems.

Do compression fittings require sealant?

No, compression fittings create a metal-to-metal seal and typically do not require sealants.

Conclusion

Hydraulic compression tee fittings are essential components in modern hydraulic systems. They provide a reliable, leak-free way to branch fluid flow while maintaining high performance under pressure. By understanding how these fittings work, their components, applications, and installation best practices, you can make informed decisions that improve system efficiency and safety.

When selecting and installing hydraulic compression tee fittings, always consider system requirements, follow manufacturer guidelines, and use quality components. To learn more or explore product options, consult hydraulic fitting experts or trusted suppliers to ensure the best solution for your application.

Post time: Dec-16-2025