Compression nuts are small but essential components used to create secure, leak-resistant connections in piping and tubing systems. Found in everything from household plumbing to complex industrial machinery, these fasteners play a critical role in safely transporting liquids and gases.

They are commonly used because they are easy to install, reliable, and do not require specialized tools, welding, or soldering. Whether in plumbing, mechanical systems, or industrial applications, compression nuts provide a dependable way to connect pipes and tubes.

Understanding how compression nuts and fittings work is important for both safety and reliability. Incorrect installation or material selection can lead to leaks, system failure, or even hazardous conditions, especially in gas or high-pressure environments. This guide explains what compression nuts are, how they work, and why they matter.

What Are Compression Nuts?

A compression nut is a threaded fastener that is part of a compression fitting system. Its primary function is to compress a ring (called a ferrule) against a pipe or tube, forming a tight seal.

How Compression Nuts Work Within a Compression Fitting System

Compression fittings rely on mechanical compression rather than adhesives or heat. When the compression nut is tightened, it squeezes the ferrule onto the tubing, locking it in place and creating a seal that prevents leaks.

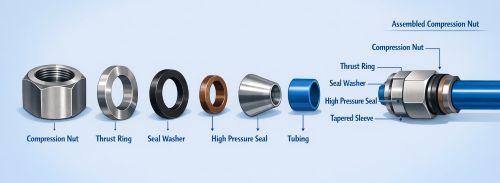

Key Components Involved

➡️ Compression Nut: The threaded nut that tightens onto the fitting body.

➡️ Compression Ring (Ferrule): A small ring that compresses against the tubing to form the seal.

➡️ Compression Fitting Body: The main fitting that houses the tubing and ferrule.

How Compression Nuts Work

Step-by-Step Compression Mechanism

1. The compression nut is slipped onto the pipe or tube.

2. The ferrule is placed behind the nut.

3. The tubing is inserted into the fitting body.

4. The nut is tightened onto the fitting body.

Creating a Secure, Leak-Proof Seal

As the nut tightens, it forces the ferrule to compress between the nut and the fitting body. This compression causes the ferrule to grip the tubing tightly while sealing against the fitting body, preventing fluid or gas from escaping.

Role of Pressure and Material Deformation

The sealing action relies on controlled deformation of the ferrule. Softer materials deform slightly to fill microscopic gaps, while harder materials provide strong mechanical grip, ensuring a durable and reliable connection.

Common Materials Used in Compression Nuts

Brass Compression Nuts

➡️ Widely used in plumbing

➡️ Excellent corrosion resistance

➡️ Easy to install and affordable

Stainless Steel Compression Nuts

➡️ High strength and durability

➡️ Resistant to corrosion and extreme temperatures

➡️ Ideal for industrial and high-pressure environments

Plastic (Nylon) Compression Nuts

➡️ Lightweight and corrosion-resistant

➡️ Suitable for low-pressure applications

➡️ Common in water filtration and plastic tubing systems

Material Comparison

➡️ Durability: Stainless steel > brass > plastic

➡️ Corrosion Resistance: Stainless steel and plastic perform best

➡️ Cost: Plastic (lowest), brass (moderate), stainless steel (highest)

Typical Use Cases:

➡️ Plastic: low-pressure water systems

➡️ Brass: household plumbing

➡️ Stainless steel: industrial and high-pressure systems

Types of Compression Nuts

Standard Compression Nuts

Used for general-purpose applications with standard tubing sizes.

Metric vs. Imperial Compression Nuts

1. Metric systems are common in Europe and Asia

2. Imperial (inch-based) systems are common in North America

Using the correct standard is essential to avoid leaks or fitting damage.

Single-Ferrule vs. Double-Ferrule Systems

1. Single-ferrule: Simpler and more affordable, common in plumbing

2. Double-ferrule: Provides enhanced sealing and vibration resistance, often used in industrial settings

Specialized Compression Nuts

Designed for extreme conditions such as high pressure, high temperature, or corrosive environments.

Where Compression Nuts Are Commonly Used

Here are the common areas where compression nuts are commonly used:

1. Plumbing systems: Water supply lines, faucets, shutoff valves

2. Gas lines and HVAC systems: Natural gas, propane, heating systems

3. Industrial machinery: Fluid transfer and pneumatic systems

4. Automotive and hydraulic applications: Fuel lines, brake systems, hydraulic tubing

Advantages of Using Compression Nuts

Here are the advantages of using compression nuts in your work:

1. Easy installation without special tools

2. Reusable and adjustable connections

3. Reliable sealing without welding or soldering

4.bIdeal for tight or hard-to-reach spaces

These benefits make compression nuts especially popular for repairs, upgrades, and installations where convenience and reliability are important.

Limitations and Potential Drawbacks

Not all the time, compression nuts can be used. Here are some considerations when you cannot rely on these nuts:

1. Not ideal for environments with extreme vibration

2. Risk of over-tightening, which can damage the ferrule or tubing

3. Limited reuse depending on ferrule type

Comparison with Alternatives

1. Flare fittings: Better for high vibration and high pressure

2. Push-to-connect fittings: Faster installation but less durable long-term

3. Threaded fittings: Strong but often require sealants and precise alignment

How to Properly Install Compression Nuts

Required Tools and Preparation

➡️ Adjustable wrench or spanner

➡️ Clean, square-cut tubing

➡️ Correctly sized compression fitting

Step-by-Step Installation Guide

1. Slide the compression nut onto the tubing.

2. Place the ferrule behind the nut.

3. Insert the tubing fully into the fitting body.

4. Hand-tighten the nut, then use a wrench to tighten further (usually ½ to 1 turn).

Proper Tightening Techniques

Tighten firmly but avoid excessive force. Over-tightening can deform the ferrule too much and cause leaks.

Common Installation Mistakes to Avoid

➡️ Using mismatched sizes or thread types

➡️ Over-tightening the nut

➡️ Reusing damaged ferrules

Maintenance and Inspection Tips

How to Check for Leaks

Inspect connections visually and test under pressure using water, air, or leak-detection solution.

When to Retighten or Replace

Retighten only if minor leaks appear. Replace the ferrule or nut if damage is visible.

Signs of Wear or Failure

➡️ Cracks in the nut

➡️ Corrosion or rust

➡️ Persistent leaks even after tightening

Compression Nuts vs. Other Fastening Solutions

1. Compression nuts vs. flare fittings: Compression fittings are easier to install, flare fittings handle vibration better.

2. Compression nuts vs. threaded fittings: Compression fittings seal without tape or sealant.

3. Compression nuts vs. push-fit connectors: Compression fittings offer greater long-term reliability.

When to Choose Compression Nuts

Choose compression nuts when you need a reliable, adjustable, and tool-friendly connection without heat or adhesives.

Safety Considerations

1. Always respect pressure and temperature limits

2. Ensure compatibility with tubing material and size

3. Use certified fittings for gas and high-pressure applications

4. Never mix incompatible materials

How to Choose the Right Compression Nut

1. Match the exact size and thread type

2. Select the correct material for the environment

3. Consider pressure, temperature, and fluid type

4. Look for industry standards and certifications (e.g., ASTM, ISO)

Frequently Asked Questions (FAQ)

Are compression nuts reusable?

Yes, in many cases, though ferrules may need replacement after removal.

Can compression nuts be used for gas lines?

Yes, if they are rated and approved for gas applications.

How tight should a compression nut be?

Typically hand-tight plus ½ to 1 wrench turn, depending on manufacturer guidelines.

Do compression fittings require sealant or tape?

No, the seal is created mechanically by the ferrule, not by thread sealants.

Conclusion

Compression nuts are simple yet highly effective components that enable secure, leak-free connections across a wide range of applications. From household plumbing to demanding industrial systems, they offer ease of installation, reliability, and versatility.

Their continued use is a testament to their proven performance and practicality. Whether you are a professional installer or a DIY enthusiast, understanding compression nuts will help you make safer, smarter, and more durable connections.

Post time: Jan-05-2026