Compression fittings connect pipes and tubing without soldering or welding and are widely used in plumbing, HVAC, and mechanical systems due to their simplicity and reliability. When a line needs to be disconnected, a common question is whether compression fittings can be reused, a decision that affects cost, convenience, and safety. While reuse may be possible in limited situations, it is not always recommended and can increase the risk of leaks.

This article explains when reuse is acceptable, when it is unsafe, and what professionals advise.

What Are Compression Fittings?

Compression fittings are mechanical connectors used to join pipes or tubing by compressing a soft metal or plastic ring to create a tight seal.

Common Materials

Compression fittings are made from several materials, depending on the application:

1. Brass (most common in plumbing)

2. Copper

3. Stainless steel

4. Plastic (often for low-pressure or specialty systems)

Typical Applications

Compression fittings are used across many industries:

1. Plumbing: water supply lines to faucets, toilets, and appliances

2. Gas lines: some low-pressure gas connections (where code allows)

3. HVAC systems: refrigerant or condensate lines

4. Hydraulic and pneumatic systems: fluid or air transfer under controlled pressures

Key Components

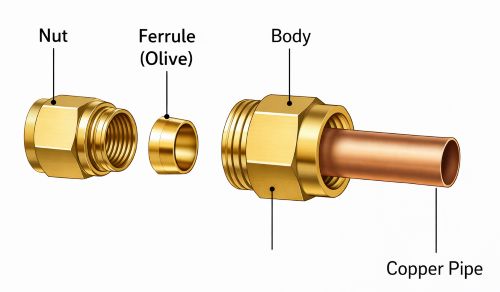

A compression fitting consists of three main parts:

➡️ Nut: tightens onto the fitting body

➡️ Ferrule (also called an olive): a ring that compresses around the pipe

➡️ Body: the main fitting housing that receives the pipe

How Compression Fittings Work

A compression fitting creates a seal through mechanical force rather than adhesives or heat.

The ferrule is forced into the fitting body when the nut is tightened. This action compresses the ferrule tightly around the pipe, forming a leak-tight seal. The ferrule slightly deforms to match the pipe’s surface, which is why installation quality is so important.

Why Proper Installation Is Critical

➡️ Overtightening can deform the ferrule too much or damage the threads

➡️ Undertightening can lead to slow leaks

➡️ Misalignment can prevent proper sealing

Compression vs. Other Fitting Types

➡️ Compression fittings: rely on ferrule compression

➡️ Flare fittings: use a flared pipe end and metal-to-metal seal

➡️ Push-fit fittings: use internal O-rings and grab rings

➡️ Threaded fittings: rely on thread sealant or tape

Each type has different reuse and reliability characteristics.

Can You Reuse Compression Fittings?

Yes, sometimes, but only under specific conditions.

Reuse is controversial because compression fittings are designed to deform slightly during installation. Once that deformation occurs, the fitting may not seal the same way again.

Differences in Reusability

1. Nut: usually reusable if threads are undamaged

2. Fitting body: often reusable if not worn or cracked

3. Ferrule: rarely recommended for reuse

When Reusing Compression Fittings Is Possible

There are situations where reuse may be acceptable, especially in low-risk environments.

Acceptable Scenarios

1. Temporary installations

2. Low-pressure water supply lines

3. Non-critical, easily accessible connections

4. When the fitting is being reinstalled on the same pipe

Ferrule Condition Matters

Reuse may be possible if the ferrule:

1. Has not deformed excessively

2. Shows no deep grooves, cracks, or corrosion

3. Still fits snugly on the pipe

Visual Inspection Checklist

➡️ No stripped threads on nut or body

➡️ No corrosion or pitting

➡️ No visible cracks

➡️ Ferrule still seats evenly

➡️ Reusing a fitting on a different pipe is far more likely to fail.

When You Should NOT Reuse Compression Fittings

In many cases, reuse is unsafe or against code.

High-Risk Applications

1. Gas lines

2. High-pressure systems

3. Concealed installations (inside walls or floors)

4. Critical systems where a malfunction could result in harm or damage

Clear Signs Replacement Is Needed

1. Deformed, seized, or stuck ferrule

2. Stripped or cross-threaded nut

3. Repeated leaks after retightening

4. Corrosion or metal fatigue

Code Considerations

Local plumbing and building codes may prohibit reuse, especially for gas and concealed plumbing. Always check local regulations.

Risks of Reusing Compression Fittings

Reusing compression fittings increases several risks:

1. Higher chance of leaks

2. Possible pipe damage from uneven compression

3. Safety hazards, especially with gas or pressurized systems

4. Reduced long-term reliability

In many cases, the cost of a new fitting is far lower than the cost of a failure.

How to Reuse a Compression Fitting Safely (If You Choose To)

If you decide to reuse a compression fitting, follow best practices to minimize risk.

Step-by-Step Guidelines

1. Carefully loosen and remove the fitting

2. Inspect nut, body, and ferrule closely

3. Clean all threads and sealing surfaces

4. Replace the ferrule if possible

5. Reinstall squarely and hand-tighten first

6. Tighten gradually—do not overtighten

7. Pressure-test the system thoroughly

Always test under operating conditions before leaving the installation unattended.

Alternatives to Reusing Compression Fittings

Often, safer and more reliable options are available.

Better Options

➡️ Replace only the ferrule (in many cases)

➡️ Install a new compression fitting

➡️ Switch to alternative connection types, like Push-to-connect fittings, Soldered fittings, and Flare fittings.

Cost vs. Reliability

While reuse saves a small amount upfront, new fittings provide better sealing, longer service life, and greater peace of mind.

What Professionals Recommend

Most plumbers and technicians avoid reusing compression fittings whenever possible.

Professional Perspective

➡️ Time spent troubleshooting leaks costs more than new parts

➡️ Liability concerns favor new fittings

➡️ Manufacturer guidelines typically discourage ferrule reuse

Limited Exceptions

Professionals may allow reuse in:

➡️ Temporary setups

➡️ Non-critical, low-pressure water lines

➡️ Situations where the ferrule is replaced

Frequently Asked Questions (FAQ)

Can you reuse compression fittings without leaks?

Sometimes, but the risk of leaks increases, especially if the ferrule is reused.

Can compression fittings be reused on copper pipes?

Only if the ferrule and pipe are in excellent condition and reused on the same pipe.

Can you reuse compression fittings for gas lines?

Generally no. This is unsafe and often prohibited by code.

What is the maximum number of reuses that a compression fitting can have?

There’s no guaranteed number. Each reuse increases the chance of failure.

Is it safe to reuse the nut but replace the ferrule?

Yes, this is often the safest compromise.

Should You Reuse Compression Fittings?

Compression fittings can sometimes be reused, but it’s not always wise. For DIYers, reuse may be acceptable in low-pressure, non-critical water systems, provided the ferrule is replaced, and everything is carefully inspected.

For professionals and critical systems, replacement is usually the best choice. Safety, reliability, and long-term performance should always outweigh minor cost savings.

When in doubt, replace the fitting, especially in gas, high-pressure, or concealed installations.

Post time: Dec-23-2025