Thread compatibility is one of the most overlooked yet critical factors in plumbing, hydraulics, pneumatics, and industrial system design. Using the wrong thread type can lead to leaks, component damage, system failure, and costly downtime. These are the issues that no engineer or technician wants to face.

Despite their similar appearance, BSP and NPT threads are not designed to work together, and understanding the differences can save you from major headaches.

This guide gives you a clear, engineer-friendly cheat sheet to understanding BSP vs NPT threads, why compatibility matters, and how to identify and work with these thread standards safely and effectively.

What Are BSP and NPT Threads?

BSP (British Standard Pipe)

BSP threads originated in the UK and are widely used throughout Europe, Asia, and many regions outside North America. They are a long-standing international standard for pipe fittings, recognized for their reliability and clear specification.

BSP threads come in two main subtypes:

1. BSPP (British Standard Pipe Parallel) – These threads are straight (parallel) and do not taper. Because of this, BSPP threads rely on sealing washers or O-rings to form a proper seal.

2. BSPT (British Standard Pipe Tapered) – These threads taper along the length, similar to NPT threads, allowing them to form a seal through thread compression.

NPT (National Pipe Thread)

NPT threads are the standard in the United States and Canada, widely used across industrial, manufacturing, and oil & gas applications. Unlike BSPP, NPT threads are always tapered, enabling sealing through metal-to-metal thread deformation.

This thread is commonly used in compressed air systems, high-pressure hydraulics, oil & gas piping, industrial equipment, and fabrication in North American markets.

Key Differences Between BSP and NPT

Understanding what sets BSP and NPT apart is essential for avoiding compatibility issues.

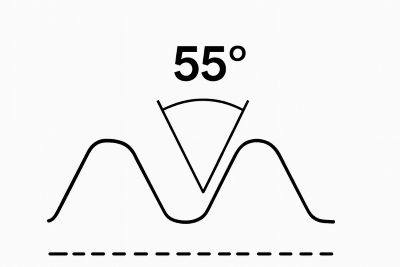

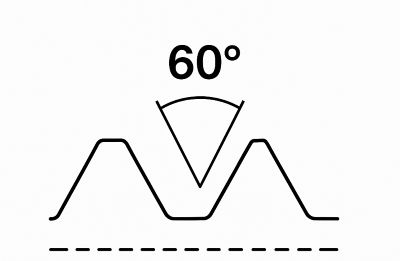

1. Thread Angle

➡️ BSP uses a 55° Whitworth angle

➡️ NPT uses a 60° thread angle

This difference in angle alone is enough to prevent proper thread seating, resulting in poor engagement and leaks.

2. Thread Shape & Crest

➡️ BSP threads have rounded peaks and valleys

➡️ NPT threads have flattened peaks

This geometric difference affects how the threads mate mechanically. Even if the diameter seems similar, the crest shapes will not align properly.

3. Pitch Differences

Thread pitch determines how many threads exist per inch (TPI) or per millimeter.

Because BSP typically follows metric-based pitch standards and NPT follows imperial TPI values, their pitch measurements commonly differ. When pitch is mismatched:

➡️ Threads cannot fully engage

➡️ Seal integrity is compromised

➡️ Overtightening can damage or strip threads

4. Taper vs Parallel Threads

➡️ BSPP = parallel

➡️ BSPT = taper

➡️ NPT = taper

Sealing mechanism differences:

➡️ BSPP relies on O-rings or sealing washers because parallel threads cannot self-seal.

➡️ BSPT seals via taper deformation.

➡️ NPT seals via metal-to-metal taper compression, often enhanced with PTFE tape or sealant.

Are BSP and NPT Threads Compatible?

Short Answer: Mostly No

Although they may look similar at a glance, BSP and NPT threads are fundamentally different in angle, pitch, crest shape, and in some cases, taper. These differences mean that BSP and NPT threads should not be mixed.

Even minor misalignments can result in failure when subjected to pressure or vibration.

Real-World Issues When Mixing Them

➡️ Leaks due to incomplete thread engagement

➡️ Thread galling or binding caused by forced mismatching

➡️ Reduced pressure rating and system inefficiency

➡️ Long-term safety risks, including catastrophic failure in critical systems

Exceptions: When Adapters Can Be Used

The safest way to combine BSP and NPT components is through BSP–NPT conversion fittings.

Best practices when using adapters:

1. Choose high-quality, pressure-rated adapters

2. Verify the correct combination of BSPP/BSPT and NPT

3. Use proper thread sealant based on the fitting type

4. Avoid stacking multiple adapters

Identifying BSP vs NPT in the Field

Correctly identifying thread type before assembly helps avoid expensive mistakes.

1. Visual Clues

➡️ Taper vs straight: NPT and BSPT are tapered, while BSPP is straight.

➡️ Look for markings, stamps, or labels indicating BSP, BSPP, BSPT, or NPT.

2. Measuring Threads

Use tools such as:

➡️ Calipers to measure major/minor diameter

➡️ Thread pitch gauges to confirm pitch

➡️ Angle gauge to distinguish between 55° and 60°

3. Quick Field Identification Tricks

➡️ If the thread is straight, it’s likely BSPP.

➡️ If it is tapered and from North America, it is likely NPT.

➡️ A thread that almost fits but binds early is typically mismatched.

Common Sizes and How They Compare

|

Nominal Size |

BSP (Major Ø mm) |

NPT (Major Ø mm) |

|

1/4″ |

~13.16 mm |

~13.72 mm |

|

1/2″ |

~20.44 mm |

~20.96 mm |

|

1″ |

~33.25 mm |

~33.40 mm |

Same-named sizes do not match dimensionally. Even when BSP and NPT diameters appear close, the other threading characteristics prevent proper interchangeability.

Best Practices for Engineers and Technicians

1. Standardize Thread Types Across Projects

➡️ Reduces confusion between teams

➡️ Minimizes adapter use

➡️ Improves maintenance efficiency

2. Use Proper Sealants

➡️ PTFE tape works well for most NPT and BSPT tapered threads

➡️ Thread paste or liquid sealants may be preferred in high-pressure or high-vibration environments

➡️ BSPP connections require washers or O-rings—not tape

3. Verify Before Assembly

➡️ Inspect components before installation

➡️ Match threads using pitch gauges and sizing charts

➡️ Keep manufacturer data sheets accessible

4. Training and Documentation

➡️ Train technicians to identify thread types visually and with measuring tools

➡️ Maintain logs of thread standards used in each machine or system

➡️ Document any conversions with adapters

BSP vs NPT Quick Comparison Chart (Cheat Sheet)

|

Feature |

BSP |

NPT |

|

Thread Angle |

55° |

60° |

|

Thread Types |

BSPP (Parallel), BSPT (Taper) |

NPT (Taper) |

|

Crest Shape |

Rounded |

Flattened |

|

Seal Type |

Washer/O-ring (BSPP), metal-to-metal (BSPT) |

Metal-to-metal taper |

|

Regional Use |

UK, Europe, Asia |

USA, Canada |

|

Interchangeability |

No |

No |

Conclusion

BSP and NPT threads may look similar, but their differences in angle, pitch, crest shape, taper, and sealing method make them largely incompatible. Engineers and technicians must identify thread types correctly to avoid leaks, failures, and added costs.

When mixing systems is unavoidable, use high-quality adapters and follow best practices to ensure safety and performance.

Choosing the correct thread type means safer systems, less downtime, and greater long-term reliability.

Post time: Dec-06-2025