In industrial piping systems, flanges serve as crucial connecting elements that join pipes, valves, pumps, and other components into a continuous network. They make it easier to assemble, disassemble, and inspect pipeline sections without the need for extensive cutting or welding. Among the various types of flanges, the blind spade flange (also known as a spade and spacer or figure-8 flange) plays a particularly important role in flow isolation, maintenance, and safety.

The ANSI / ASME blind spade flange is designed to isolate flow in a controlled, reliable, and safe manner, particularly during maintenance or testing. Because it adheres to ANSI / ASME standards, it guarantees dimensional accuracy, interchangeability, and compatibility with other standardized piping components across industries.

Understanding the ANSI / ASME Blind Spade Flange

A. What Is a Blind Spade Flange?

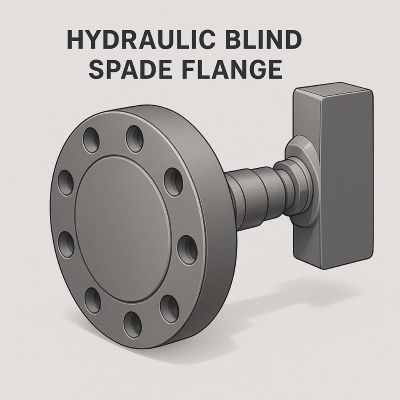

A blind spade flange is a specialized pipeline component consisting of a solid metal plate (the spade) that can be inserted between two pipe flanges to block the flow of fluid. It’s part of a family of components often referred to as spade and spacer sets or spectacle blinds.

➡️ Spade (Blind): A solid plate used to stop the flow.

➡️ Spacer (Ring): A ring with a central hole used to allow flow.

➡️ Spectacle Blind: A combination of both spade and spacer joined by a metal tie bar, resembling a “figure 8.”

These components are commonly used in pipelines where temporary isolation is needed for inspection, cleaning, or repair.

B. How It Works

The blind spade flange is installed between two pipe flanges. During normal operation, a spacer is used to keep the line open. When the line needs to be isolated, the spade replaces the spacer, effectively blocking flow.

Common use cases include:

➡️ Scheduled maintenance or shutdowns

➡️ Hydrostatic testing of specific pipeline sections

➡️ Inspection and cleaning of piping systems

➡️ Safety isolation to prevent accidental flow during repairs

This simple yet effective design allows operators to switch between flow and isolation without permanently altering the pipeline configuration.

Standards and Specifications

A. ANSI / ASME Design Standards

Blind spade flanges are designed and manufactured in accordance with ANSI / ASME standards to ensure global compatibility and performance reliability. The two primary standards are:

➡️ ASME B16.5 – Pipe Flanges and Flanged Fittings (up to 24 inches)

➡️ ASME B16.47 – Large Diameter Steel Flanges (26 to 60 inches)

These standards define dimensions, pressure classes, facing types, and tolerances to ensure proper fit and safety. Compliance with these codes guarantees that the flange can handle specified pressure and temperature ratings while maintaining structural integrity.

B. Pressure Ratings and Sizes

Blind spade flanges are available in a range of pressure classes such as 150#, 300#, 600#, 900#, 1500#, and 2500#, each corresponding to a specific maximum working pressure. Standard diameters range from ½ inch to 60 inches, with thickness determined by both pressure class and material strength.

Materials and Manufacturing

A. Common Materials Used

Different industries and service conditions require different materials. Common options include:

➡️ Carbon Steel (ASTM A105): Cost-effective and strong; suitable for most industrial applications.

➡️ Stainless Steel (304, 316): Corrosion-resistant and ideal for chemical or marine environments.

➡️ Alloy & Duplex Steels: High-strength materials designed for extreme temperatures and corrosive conditions.

B. Manufacturing and Quality Assurance

Blind spade flanges are forged and machined with precision to meet dimensional and mechanical requirements. The process typically includes:

1. Forging and CNC Machining: Ensures superior strength and dimensional accuracy.

2. Surface Finishes and Coatings: Options include galvanized, painted, or PTFE-coated surfaces to resist corrosion.

3. Inspection and Testing: Non-destructive testing (NDT), hydrotesting, and dimensional inspections ensure product integrity.

4. Certifications: Provided per EN 10204 3.1 / 3.2, confirming traceability and compliance.

Key Features and Advantages

1. Precision-engineered for perfect sealing and dimensional fit

2. Quick installation and removal, minimizing downtime

3. Excellent corrosion and pressure resistance

4. Complies with ANSI / ASME and international piping standards

5. Improves operational safety during isolation and maintenance

These attributes make the blind spade flange an essential component in high-stakes industries where performance and safety are non-negotiable.

Applications Across Industries

The ANSI / ASME blind spade flange is used wherever pipelines must be isolated for inspection or maintenance. Common sectors include:

➡️ Oil and Gas Pipelines

➡️ Petrochemical and Refining Plants

➡️ Power Generation Facilities

➡️ Water Treatment and Desalination Plants

➡️ Marine and Offshore Platforms

Its versatility makes it suitable for both onshore and offshore environments, handling liquids, gases, and corrosive media.

How to Choose the Right Blind Spade Flange

Selecting the correct flange involves evaluating several factors:

1. Pipe Size and Pressure Rating: Match to the pipeline’s ANSI / ASME class and diameter.

2. Material Compatibility: Ensure the material suits the medium (oil, water, chemicals, etc.).

3. Operating Temperature and Pressure: Confirm that the flange can withstand the system’s conditions.

4. Industry Standards and Certifications: Always verify compliance with ASME codes and manufacturer certificates.

Pro Tip: Always request Material Test Certificates (MTC) and verify that dimensions and pressure ratings meet the required standard before installation.

Installation and Maintenance Tips

1. Ensure safety first: Fully depressurize and drain the pipeline before installation or removal.

2. Use the correct bolt tightening sequence to achieve even gasket compression and prevent leaks.

3. Conduct periodic inspections to identify corrosion or damage.

4. Store properly: Keep spades and spacers clean, dry, and protected from mechanical damage or rust.

Why Choose Sannke

At Sannke, we specialize in manufacturing and supplying ANSI / ASME compliant blind spade flanges that meet the most demanding industrial requirements.

Our advantages include:

➡️ Advanced forging and CNC machining facilities

➡️ Strict quality assurance and testing standards

➡️ Customization options for materials, coatings, and dimensions

➡️ Global supply capability with timely delivery

➡️ Dedicated technical support for product selection and engineering advice

When precision, reliability, and safety matter most — trust Sannke.

FAQ

Q1: What is the difference between a blind flange and a blind spade flange?

A blind flange permanently seals the end of a pipe, while a blind spade flange temporarily isolates flow between two flanges.

Q2: Can a spade flange be used in high-pressure applications?

Yes. When designed and rated according to ASME standards (e.g., 600# or higher), spade flanges perform reliably under high-pressure conditions.

Q3: What standards govern the dimensions of spade flanges?

Spade flanges follow ASME B16.5 for sizes up to 24 inches and ASME B16.47 for sizes above 24 inches, ensuring dimensional consistency and safety compliance.

Conclusion

The ANSI / ASME blind spade flange is a vital safety and isolation component in modern piping systems. Engineered to meet strict international standards, it ensures safe maintenance, controlled flow isolation, and operational reliability across diverse industrial environments.

Contact us today to request a custom quotation, technical datasheet, or expert guidance on selecting the right flange for your application.

Post time: Oct-21-2025