When it comes to brake systems, whether on cars, motorcycles, or high-performance vehicles, every small component plays a big role in ensuring safety and precision. Among these components, brake line fittings are essential for maintaining a secure and leak-free connection within the hydraulic system.

One of the most popular and versatile fitting types is the banjo brake line fitting. Compact, efficient, and perfect for tight spaces, banjo fittings are the go-to choice for many automotive and motorcycle applications.

In this article, we’ll cover everything you need to know about banjo brake line fittings, how they work, the different types available, materials and finishes, installation best practices, maintenance tips, and common troubleshooting advice.

What Are Banjo Brake Line Fittings?

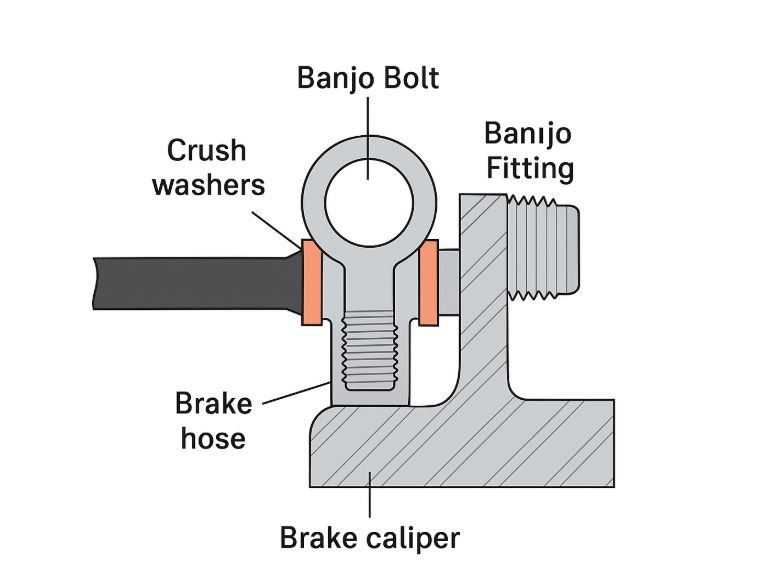

A banjo brake line fitting is a specialized hydraulic connector designed to join a brake hose or line to a component, usually a brake caliper or master cylinder, using a hollow, bolt-through connection.

Unique Design Features:

➡️ Banjo Bolt: A hollow bolt that allows fluid to pass through its center.

➡️ Banjo Fitting (Eye): The circular fitting with a hole for the bolt to pass through.

➡️ Crush Washers: Usually made of copper or aluminum, these sit on either side of the banjo fitting to create a tight, leak-free seal.

This configuration allows brake fluid to flow efficiently while maintaining a compact profile, ideal for tight or complex installations.

Common Applications:

1. Automotive and motorcycle brake systems

2. Hydraulic clutch lines

3. Heavy machinery and off-road vehicles

How Banjo Brake Line Fittings Work

At its core, a banjo fitting operates by allowing pressurized brake fluid to flow through the hollow bolt into the attached fitting and line. When the banjo bolt is tightened, the crush washers deform slightly to seal the connection and prevent any leakage.

Step-by-Step Fluid Path:

1. Brake fluid enters the banjo bolt through the hollow shaft.

2. It flows out through the side port into the banjo fitting.

3. The fluid continues through the brake hose to the caliper.

4. When the brake pedal is pressed, fluid pressure applies force to the caliper pistons, engaging the brakes.

Key Details:

1. Proper washer placement (one on each side of the banjo fitting) is crucial.

2. Torque must meet manufacturer specifications to ensure an optimal seal.

3. Common thread sizes: M10x1.0, M10x1.25, 3/8″-24, and others depending on the vehicle.

Types of Banjo Brake Line Fittings

Banjo fittings come in several configurations to suit different installation needs.

|

Type |

Description |

Common Use |

|

Straight Banjo Fitting |

Standard, direct connection between brake line and caliper |

Most OEM brake setups |

|

45° Angled Fitting |

Allows line routing around obstacles |

Custom or tight installations |

|

90° Angled Fitting |

Sharp bend for minimal clearance areas |

Motorcycles or racing setups |

|

Single Banjo Fitting |

Connects one brake line to a component |

Standard use |

|

Double Banjo Fitting |

Allows two lines on one bolt |

Dual-caliper or linked brake systems |

Materials and Finishes

Choosing the right material ensures both performance and longevity.

Common Materials:

➡️ Stainless Steel – Highly durable, corrosion-resistant, ideal for performance and long-term use.

➡️ Aluminum – Lightweight and easy to handle, often anodized for extra protection.

➡️ Brass – Provides excellent sealing and flexibility, commonly used in hydraulic applications.

Finishes:

➡️ Anodized (for color and corrosion resistance)

➡️ Zinc-Plated (for added protection)

➡️ Raw Metal (for easy polishing or custom coating)

Use stainless steel fittings for vehicles exposed to moisture or salt, and aluminum for weight-sensitive applications.

Benefits of Using Banjo Fittings

➡️ Compact Design: Perfect for installations with limited space.

➡️ Leak-Free Performance: Properly sealed crush washers ensure reliable hydraulic pressure.

➡️ Easy Maintenance: Quick removal and replacement.

➡️ Custom Compatibility: Works well with performance or aftermarket brake setups.

➡️ Aesthetic Appeal: Available in polished or anodized finishes—ideal for show-quality builds.

How to Install Banjo Brake Line Fittings

Tools Required:

1.Open-end or socket wrenches

2. Torque wrench

3. New crush washers

4. Thread pitch gauge

Step-by-Step Installation:

1. Inspect Components: Ensure all parts are clean and free from debris.

2. Position Washers: Place one crush washer between the caliper and fitting, and another between the fitting and bolt head.

3. Insert and Tighten Bolt: Hand-tighten first, then torque to the manufacturer’s specification (usually 25–35 Nm for M10 bolts).

4. Check for Leaks: Pressurize the system and inspect for any fluid seepage.

5. Final Step: Always replace crush washers with new ones during reinstallation.

6. Safety Tip: Never reuse old crush washers, they won’t reseal properly.

Brake Torque Specification Chart (Common Vehicles)

|

Vehicle Make & Model |

Banjo Bolt Torque (Nm) |

Banjo Bolt Torque (ft-lb) |

Caliper Mounting Bolt Torque (Nm) |

Caliper Mounting Bolt Torque (ft-lb) |

|

Honda Civic (2016–2021) |

30 Nm |

22 ft-lb |

110 Nm |

81 ft-lb |

|

Toyota Corolla (2014–2022) |

25 Nm |

18 ft-lb |

107 Nm |

79 ft-lb |

|

Mazda 3 (2014–2020) |

28 Nm |

21 ft-lb |

105 Nm |

77 ft-lb |

|

Ford F-150 (2015–2022) |

35 Nm |

26 ft-lb |

175 Nm |

129 ft-lb |

|

Chevrolet Silverado 1500 (2014–2021) |

33 Nm |

24 ft-lb |

190 Nm |

140 ft-lb |

|

Subaru WRX (2015–2021) |

27 Nm |

20 ft-lb |

118 Nm |

87 ft-lb |

|

BMW 3 Series (F30, 2012–2019) |

35 Nm |

26 ft-lb |

110 Nm |

81 ft-lb |

|

Mercedes-Benz C-Class (W205, 2015–2021) |

30 Nm |

22 ft-lb |

130 Nm |

96 ft-lb |

|

Nissan Altima (2013–2020) |

26 Nm |

19 ft-lb |

95 Nm |

70 ft-lb |

|

Hyundai Elantra (2017–2022) |

25 Nm |

18 ft-lb |

100 Nm |

74 ft-lb |

|

Jeep Wrangler (JL, 2018–2023) |

33 Nm |

24 ft-lb |

125 Nm |

92 ft-lb |

|

Harley-Davidson (Touring Models) |

34 Nm |

25 ft-lb |

45 Nm |

33 ft-lb |

|

Yamaha R1 / R6 (Sportbikes) |

30 Nm |

22 ft-lb |

40 Nm |

30 ft-lb |

|

Kawasaki Ninja ZX-6R / ZX-10R |

28 Nm |

21 ft-lb |

38 Nm |

28 ft-lb |

|

Ducati Panigale Series |

32 Nm |

24 ft-lb |

42 Nm |

31 ft-lb |

Common Problems and Troubleshooting

|

Problem |

Likely Cause |

Solution |

|

Leak at fitting joint |

Reused or misaligned washers |

Replace washers, retorque to spec |

|

Cross-threading |

Incorrect bolt alignment |

Inspect threads, replace damaged parts |

|

Over-tightening |

Excess torque damaging washers |

Follow torque spec guidelines |

|

Air in brake lines |

Improper bleeding after install |

Bleed brakes thoroughly to remove air |

Maintenance Tips

➡️ Inspect banjo connections regularly for corrosion or fluid residue.

➡️ Replace fittings or washers during major brake service.

➡️ Maintain torque within manufacturer limits.

➡️ Avoid mixing materials (e.g., aluminum fitting with steel bolt) to prevent galvanic corrosion.

➡️ Use only compatible brake fluids for your system (DOT 3, DOT 4, DOT 5, etc.).

Banjo Fittings for Performance Upgrades

For performance enthusiasts, upgrading to high-quality banjo fittings can noticeably enhance braking feel and reliability.

Benefits:

1. Improved brake modulation and response.

2. Consistent hydraulic pressure under high load.

3. Perfect pairing with stainless braided brake lines for racing or off-road applications.

Example: A sportbike fitted with stainless banjo fittings and braided lines offers sharper braking performance and a cleaner look.

Conclusion

Banjo brake line fittings are small but crucial components that ensure your brake system operates efficiently and safely. Their compact design, leak-free performance, and versatility make them an indispensable part of both factory and custom brake systems.

Quick Checklist:

➡️ Choose the right fitting type for your setup.

➡️ Install with new crush washers and correct torque.

➡️ Inspect regularly for wear or leaks.

FAQs

Q: Can I reuse banjo bolts or crush washers?

A: You can reuse banjo bolts if undamaged, but always replace crush washers to ensure a proper seal.

Q: Are all banjo fittings universal?

A: No, they come in various thread sizes and angles, always match your fitting to your brake system specifications.

Q: How do I know if my banjo fitting is leaking?

A: Check for fluid residue or damp spots around the connection after applying brake pressure. Any sign of leakage means the fitting needs to be rechecked and retorqued.

Post time: Nov-10-2025