Modern plumbing and piping systems are increasingly designed within compact environments, think apartment kitchens, mechanical rooms, machinery enclosures, and retrofit projects where space is already spoken for. These tight conditions demand solutions that are efficient, reliable, and easy to install without compromising system performance.

Working in confined or hard-to-reach areas introduces a unique set of challenges, from limited tool access to higher risks of installation errors. This is where 90 degree compression fittings shine. Designed to redirect flow at a right angle while maintaining a secure seal, they offer a practical and dependable solution for space-restricted installations.

In this article, you’ll learn what 90-degree compression fittings are, why they’re so effective in tight spaces, how they compare to other fitting types, and best practices for installation and long-term performance.

Understanding 90 Degree Compression Fittings

A 90 degree compression fitting is a type of pipe fitting that changes the direction of a pipe run by 90 degrees using a compression-based sealing mechanism. Unlike fittings that require welding or threading, compression fittings rely on mechanical pressure to form a tight seal.

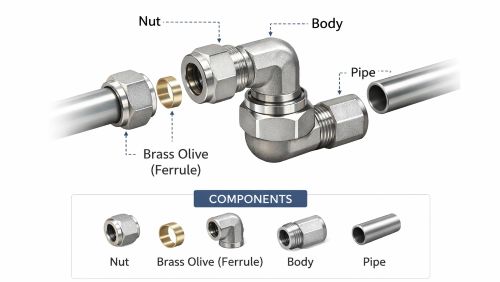

Key Components

1. Compression nut: Tightens onto the fitting body and applies pressure

2. Ferrule (or olive): Compresses around the pipe to create the seal

3. Fitting body: Houses the components and directs flow at a right angle

How the Seal Works

When the compression nut is tightened, the ferrule is pressed firmly against the pipe and fitting body. This compression creates a leak-proof seal without altering the pipe’s structure.

Common Materials

90 degree compression fittings are available in a range of materials to suit different applications:

➡️ Brass

➡️ Stainless steel

➡️ Copper

➡️ Plastic (for low-pressure or specialized systems)

Challenges of Tight-Space Installations

Installing pipes in confined areas is rarely straightforward. Some of the most common challenges include:

1. Limited access for tools and hands, making precise work difficult

2. Difficulty bending pipes without kinking, cracking, or weakening them

3. Risk of leaks caused by misalignment or rushed installation

4. Increased labor time and costs due to awkward working conditions

5. Safety concerns, especially in enclosed or poorly ventilated spaces

These issues make it essential to choose fittings designed specifically for compact environments.

How 90 Degree Compression Fittings Solve Space Constraints

The design of 90 degree compression fittings directly addresses the problems of tight installations.

1. Right-angle design allows sharp directional changes without extra components

2. Eliminates the need for pipe bending, preserving pipe integrity

3. Compact structure takes up less space than traditional elbow joints

4. Easy alignment even when visibility and movement are limited

5. Minimal clearance required, ideal for close walls or enclosures

By simplifying direction changes, these fittings reduce complexity and installation time.

Key Benefits of Using 90 Degree Compression Fittings in Tight Spaces

Using 90 degree compression fittings offers several clear advantages:

➡️ Space-saving and compact design

➡️ Quick and straightforward installation

➡️ Reduced risk of leaks when properly installed

➡️ No welding, soldering, or threading required

➡️ Easy disassembly for maintenance or adjustments

➡️ Improved overall system reliability in confined environments

These benefits make them especially attractive for both professionals and DIY installers working in restricted spaces.

Common Applications in Confined Areas

90 degree compression fittings are widely used across residential, commercial, and industrial settings, including:

➡️ Under-sink plumbing installations

➡️ Behind walls and inside cabinets

➡️ HVAC systems with limited pipe or duct clearance

➡️ Industrial machinery and equipment enclosures

➡️ Hydraulic and pneumatic systems

➡️ Retrofit and repair projects where existing layouts can’t be changed

Their versatility makes them a go-to choice whenever space is limited.

Comparison with Alternative Fitting Types

1. Compression vs Threaded Elbow Fittings

Threaded elbows often require more clearance for rotation and sealing tape, while compression fittings can be installed with minimal movement and fewer steps.

2. Compression vs Welded Joints

Welded joints are permanent and require heat, tools, and expertise—often impractical in tight spaces. Compression fittings offer flexibility, speed, and removability.

Key Differences

➡️ Performance: Comparable sealing when installed correctly

➡️ Space efficiency: Compression fittings are more compact

➡️ Installation: Faster and safer in confined areas

➡️ Cost and upkeep: Cheaper labor and simpler upkeep in the future

Installation Tips for Tight Spaces

To ensure optimal performance, follow these best practices:

1. Measure and plan the pipe layout before installation

2. Select the correct fitting size and material for the application

3. Use tools designed for confined areas, such as compact wrenches

4. Tighten carefully to avoid over-compression of the ferrule

5. Always test the system for leaks after installation

6. Proper preparation makes a significant difference in tight environments.

Maintenance and Long-Term Performance

Compression fittings are known for their durability, even in confined spaces. Over time, periodic inspection is recommended.

1. Watch for signs of wear, corrosion, or moisture

2. Re-tighten fittings if minor leaks develop

3. Replace ferrules or fittings if sealing surfaces are damaged

4. Use compatible materials to prevent long-term degradation

5. With proper care, these fittings can provide reliable service for years.

Conclusion

90 degree compression fittings are an ideal solution for tight-space installations thanks to their compact design, ease of installation, and dependable sealing performance. They eliminate many of the challenges associated with confined environments while improving efficiency and safety.

Whether you’re working under a sink, inside a cabinet, or within industrial equipment, these fittings offer a practical and flexible alternative to traditional joints.

Ready to improve your next installation? Choose high-quality 90 degree compression fittings, consult a professional when needed, and explore fitting options designed specifically for tight spaces.

Post time: Jan-26-2026