When it comes to connecting fluid or gas lines securely, flare fittings are a trusted choice across many industries, from aerospace and hydraulics to HVAC and automotive systems. These fittings provide a metal-to-metal seal that ensures a tight, leak-free connection capable of withstanding pressure, vibration, and temperature changes.

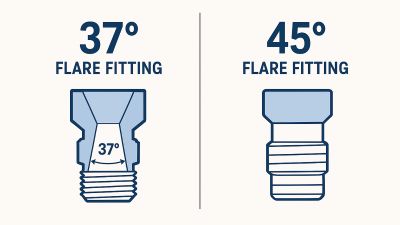

But not all flare fittings are created equal. The flare angle, either 37 degrees or 45 degrees, makes a big difference in performance, safety, and compatibility. Using the wrong type can lead to leaks, damaged components, or even complete system failure.

By the end of this article, you’ll understand exactly how 37° and 45° flare fittings differ, how to identify them, and how to choose the right one for your system.

What Are Flare Fittings?

A flare fitting is a type of mechanical connection used to join sections of tubing to other components such as valves, pumps, or manifolds. The end of the tubing is flared outward using a specialized tool to form a cone-shaped seal. When the nut on the fitting is tightened, the flare mates with the fitting’s cone surface to create a strong, leak-proof seal — without the need for additional sealing materials like tape or O-rings.

How Flaring Creates a Leak-Proof Seal

The precision of the flare and matching angle between the tube and fitting ensures that when tightened, the connection distributes pressure evenly across the sealing surface. This results in a secure joint capable of handling pressure fluctuations and vibration.

Industries That Use Flare Fittings

-

37° fittings: Commonly found in aerospace, hydraulics, and heavy machinery due to their ability to handle high-pressure conditions.

-

45° fittings: Frequently used in HVAC, refrigeration, automotive, and plumbing systems, where pressures are generally lower.

Understanding the 37° and 45° Angles

A. The 37° Flare (JIC / AN Standard)

The 37° flare fitting follows JIC (Joint Industry Council) and AN (Army-Navy) specifications. These fittings are typically made from carbon steel or stainless steel, materials chosen for their durability and strength in demanding environments.

-

Applications: High-pressure hydraulic systems, fuel delivery, and aerospace equipment.

-

Advantages: Excellent vibration resistance, high-pressure capacity (up to 10,000 PSI), and consistent performance in tough conditions.

-

Sealing Mechanism: The flare on the tube seats directly against the fitting’s cone, forming a robust metal-to-metal seal.

B. The 45° Flare (SAE Standard)

The 45° flare follows the SAE (Society of Automotive Engineers) standard and is commonly made from brass or copper. These materials are easier to form and more suitable for systems where lower pressures are involved.

-

Applications: HVAC systems, refrigeration lines, brake systems, and fuel lines.

-

Advantages: Easy to assemble, cost-effective, and ideal for soft tubing materials.

-

Pressure Range: Typically handles pressures up to about 1,000 PSI, much lower than 37° fittings.

Key Differences Between 37° and 45° Flare Fittings

|

Feature |

37° Flare (JIC/AN) |

45° Flare (SAE) |

|

Flare Angle |

37 degrees |

45 degrees |

|

Standard |

JIC / AN |

SAE |

|

Common Materials |

Steel, stainless steel |

Brass, copper |

|

Typical Use |

High-pressure hydraulics |

Low- to medium-pressure HVAC & automotive |

|

Seal Type |

Metal-to-metal |

Metal-to-metal |

|

Pressure Rating |

Up to 10,000 PSI |

Up to ~1,000 PSI |

|

Interchangeable? |

❌ No |

❌ No |

37° and 45° flare fittings are not interchangeable. Even though they may look similar, the difference in angle means they will not seal properly when mixed, leading to leaks or fitting damage.

How to Identify Flare Fitting Angles

Because the angle difference is subtle, identifying flare types by sight alone can be tricky. Here are some reliable methods:

-

Visual inspection: A 45° flare appears slightly wider and more open than a 37°.

-

Use a flare gauge or protractor: These tools measure the exact angle of the flare.

-

Check markings: Look for part numbers or standards (e.g., “JIC,” “AN,” or “SAE”) stamped on the fitting.

Why Choosing the Correct Flare Matters

Selecting the correct flare angle isn’t just about compatibility, it’s about safety and reliability. Using the wrong type of flare can cause:

-

Leaks under pressure

-

System failure or component damage

-

Safety hazards, especially in hydraulic or refrigerant systems

-

Costly downtime due to repairs or replacements

-

Violation of safety or industry standards

A mismatched flare fitting may hold temporarily, but under real-world conditions, heat, vibration, or pressure spikes, it can fail catastrophically.

How to Choose Between 37° and 45° Fittings

Choosing the right flare angle depends on your system type, tubing material, and pressure requirements:

-

Use 37° (JIC/AN) fittings with steel or stainless-steel tubing in high-pressure systems.

-

Use 45° (SAE) fittings with copper or brass tubing in HVAC, automotive, or refrigeration applications.

-

Always ensure that fittings, nuts, and flaring tools are designed for the same standard.

-

When in doubt, consult the equipment manufacturer’s specifications before replacing or modifying fittings.

Tips for Proper Flare Installation

To get the best performance and longest service life from your flare fittings, follow these best practices:

-

Use the correct flaring tool for your angle type (37° or 45°).

-

Inspect the flare for cracks, uneven edges, or thin walls before assembly.

-

Avoid overtightening and always follow the torque specifications provided by the manufacturer.

-

Replace damaged fittings immediately rather than attempting to reflare or reuse.

Proper installation ensures a perfect seal and reduces the risk of leaks or failures down the road.

Common Questions (FAQ)

Q1. Can I use a 37° fitting on a 45° flare?

No. The angles don’t match and will not create a reliable seal.

Q2. Are JIC and AN fittings the same?

Almost, they share the same 37° angle, but AN fittings are made to tighter tolerances for aerospace applications.

Q3. What happens if I mix brass and steel fittings?

It can cause galvanic corrosion, especially in moist environments. Always match materials when possible.

Q4. Can I convert from one flare type to another?

Yes, with special adapter fittings, but this is not recommended for high-pressure applications.

Conclusion

The difference between 37° and 45° flare fittings may seem small, just eight degrees, but it has a huge impact on performance and safety. Using the wrong flare angle can lead to leaks, damage, and costly downtime.

Always match your fittings to your system’s specifications, and double-check standards before installation. When used correctly, both 37° and 45° flare fittings can provide years of reliable, leak-free service.

Post time: Oct-31-2025