In the world of mechanical engineering and industrial manufacturing, even the smallest components can determine the success or failure of a project. Threads are among the most critical elements, responsible for securing joints, maintaining alignment, and enabling disassembly when needed. Poor thread precision can lead to loose connections, leaks, or even catastrophic failures in machines and systems.

That’s where thread adapters come into play.

This guide explores the 2A thread adapter, explaining what “2A” means, how its dimensions and tolerances are defined, and how to ensure compatibility when integrating it into your design or repair work.

Understanding Thread Classes and Standards

Thread dimensions and classifications are governed by organizations such as ANSI (American National Standards Institute) and ASME (American Society of Mechanical Engineers). These standards define the geometry, tolerances, and fit of threaded components to ensure interchangeability and reliability across manufacturers.

Thread Class Basics

Threads are categorized into Class A and Class B, where:

-

A designates external threads (such as bolts or adapter exteriors),

-

B designates internal threads (like nuts or threaded holes).

Each class—1, 2, or 3—defines how tight or loose the fit will be between mating threads.

Where 2A Fits In

A 2A thread refers to an external thread with a medium or standard fit. It strikes a balance between the loose 1A fit (which allows quick assembly) and the tight 3A fit (which prioritizes precision and strength). This makes 2A threads ideal for general-purpose engineering where reliability and ease of use are both important.

|

Thread Class |

Fit Type |

Typical Application |

|

1A |

Loose fit |

Quick assembly, easy disassembly |

|

2A |

Standard fit |

General-purpose engineering |

|

3A |

Tight fit |

Precision, high-strength applications |

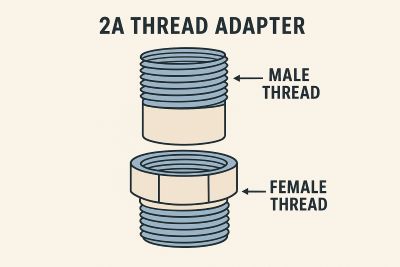

What Is a 2A Thread Adapter?

A 2A thread adapter features an external 2A thread that mates with an internal 2B thread. It acts as a bridge between components that may otherwise be incompatible due to differing thread forms or materials.

These adapters enable secure connections across mixed systems, such as joining different thread pitches, connecting imperial to metric threads, or ensuring consistent sealing and torque transfer.

Common Uses

2A thread adapters are commonly used in:

-

Industrial machinery – for connecting interchangeable tools and parts

-

Automotive systems – in fittings, sensors, and fuel components

-

Aerospace assemblies – where lightweight precision connectors are required

-

Plumbing and electronics – to adapt between thread types for functional integration

Dimensions and Measurement

Thread Dimensions Explained

A thread’s geometry is defined by several key diameters:

-

Major Diameter: The largest diameter of the thread (crest to crest).

-

Minor Diameter: The smallest diameter (root to root).

-

Pitch Diameter: The midpoint where the thread thickness equals the thread groove.

Measurement Units

Threads may follow either:

-

Unified Thread Standard (UTS) – used primarily in the U.S.

-

Metric thread systems – used globally and defined in millimeters.

Example: ¼”-20 UNC 2A Thread Adapter

-

¼” = nominal major diameter (0.25 inches)

-

20 = threads per inch (TPI)

-

UNC = Unified National Coarse thread series

-

2A = external thread class (standard fit)

Tools Used for Measurement

Precision measurement tools include:

-

Thread gauges – to check pitch and fit

-

Micrometers and calipers – for accurate diameter readings

-

Optical comparators – for detailed profile inspection in industrial settings

Tolerances and Fit

Tolerance refers to the allowable deviation from nominal dimensions during manufacturing. It ensures that parts from different batches or manufacturers still fit properly.

2A Tolerance Characteristics

2A threads have a medium tolerance range, providing a good balance between manufacturing ease and reliable assembly. This allows smooth threading without excessive looseness.

2A vs 3A Comparison

-

2A: Easier to assemble, less prone to galling, suitable for general use.

-

3A: Tighter, more precise, but requires higher manufacturing accuracy and can seize if over-torqued.

Impact on Performance

Proper tolerances affect:

-

Thread engagement: Determines how much load is distributed across threads.

-

Strength: Balanced fits prevent stripping or loosening.

-

Ease of assembly: Medium tolerances allow repeatable installation and removal.

Compatibility and Mating Threads

A 2A external thread is designed to pair with a 2B internal thread. This pairing ensures a secure yet smooth connection under standard manufacturing tolerances.

When selecting components, ensure that:

-

Thread class (2A with 2B) matches,

-

Thread pitch and series (UNC, UNF, etc.) align, and

-

Thread size corresponds to the intended design.

Material Considerations

Using different materials can impact thread performance:

-

Steel to aluminum – prevent over-tightening to avoid stripping.

-

Stainless steel to stainless steel – apply anti-seize compound to prevent galling.

-

Brass to steel – ideal for corrosion resistance and smooth engagement.

Example Applications

-

Stainless steel 2A adapters in marine environments for corrosion resistance.

-

Aluminum 2A adapters in lightweight aerospace assemblies.

Common Applications of 2A Thread Adapters

-

Engineering & Manufacturing: Used in machine tool setups, fixtures, and equipment assemblies.

-

Automotive Industry: Essential for connecting fittings, sensors, or fluid system adapters.

-

Aerospace: Lightweight, precision-engineered adapters ensure secure yet serviceable joints.

-

DIY & Hobby Use: Popular in tripods, camera mounts, and modular setups that require standardized threads.

Troubleshooting and Best Practices

Common Issues

-

Cross-threading: Misaligned threads can cause permanent damage.

-

Mismatched classes: Pairing 2A with 3B may lead to poor fit.

-

Loose or tight fits: Check tolerances if parts don’t assemble smoothly.

Checking Compatibility

Always verify:

-

Thread type (UNC, UNF, metric)

-

Size and pitch

-

Class (2A with 2B)

Thread Lubrication

Using lubricants or anti-seize compounds helps prevent galling, corrosion, and over-tightening.

Maintaining Thread Integrity

Keep threads clean, avoid contamination, and use torque specifications to prevent premature wear.

2A Thread vs 2B Thread Adapter

While 2A refers to external threads, 2B applies to internal threads.

-

2A adapters offer moderate clearance, allowing easy assembly.

-

2B threads provide slightly tighter tolerance to ensure reliable engagement.

Together, they form a balanced connection widely used in general-purpose engineering.

Here’s a quick comparison of 2A thread vs 2B thread:

|

Feature |

2A Thread (External) |

2B Thread (Internal) |

|

Type |

External (male thread, e.g., bolt, stud) |

Internal (female thread, e.g., nut, tapped hole) |

|

Fit Class |

Class 2 — general-purpose |

Class 2 — general-purpose |

|

Fit Relationship |

Designed to fit into 2B internal threads |

Designed to accept 2A external threads |

|

Tolerance (clearance) |

Slightly smaller pitch diameter for clearance |

Slightly larger pitch diameter for clearance |

|

Typical Use |

Bolts, screws, studs used in general assemblies |

Nuts, threaded holes for general assemblies |

|

Ease of Assembly |

Easy to screw into 2B threads by hand |

Accepts 2A threads smoothly with minor play |

|

Precision Level |

Medium (balance of fit and ease) |

Medium (balance of fit and strength) |

|

Interchangeability |

Works with all standard 2B internal threads |

Works with all standard 2A external threads |

|

Common Applications |

Machinery, automotive, consumer products, hardware |

Machinery, housings, fittings, general fasteners |

|

Plating/Coating Allowance |

Has allowance for coatings and plating thickness |

Usually manufactured slightly larger to maintain fit with coated 2A |

|

Tolerance Grade Comparison |

Tighter than Class 1A, looser than Class 3A |

Tighter than Class 1B, looser than Class 3B |

|

Gauge Check (Inspection) |

GO gauge must pass; NO-GO gauge must not |

GO gauge must pass; NO-GO gauge must not |

|

Pros |

Common, easy to produce, fits coated parts |

Standard, reliable, easy assembly |

|

Cons |

Not as tight as Class 3A (less precision) |

Not as tight as Class 3B (slightly more play) |

Key Takeaways

Understanding thread classifications like 2A isn’t just about numbers. It’s about ensuring mechanical reliability, safety, and efficiency. Whether you’re designing industrial machinery or assembling a DIY project, knowing how to choose the right thread adapter can make all the difference.

A few notes:

-

2A thread adapters offer a balanced fit between precision and ease of use.

-

Tolerances directly affect assembly performance and thread life.

Always match 2A with 2B for proper compatibility.

Post time: Nov-06-2025