Our flange fittings are engineered to meet and exceed industry standards for reliability and performance. We base our design on the installation design standards specified in ISO 12151, which ensure compatibility with other fittings in hydraulic systems.

In addition to the ISO 12151 standard, we also incorporate design standards such as ISO 6162 and SAE J518 into our flange fittings. These specifications enhanced the design and performance of our flange fittings, ensuring that they meet the highest standards of quality and dependability.

To further enhance the performance of our flange fittings, we have modeled the hydraulic core and sleeve after Parker’s 26 series, 43 series, 70 series, 71 series, 73 series, and 78 series. This allows our flange fittings to be used as a perfect replacement option for Parker’s hose fittings, providing greater flexibility and compatibility in hydraulic systems.

With Sannke, you can be confident that you are getting a product that is efficient, reliable, and built to last.

-

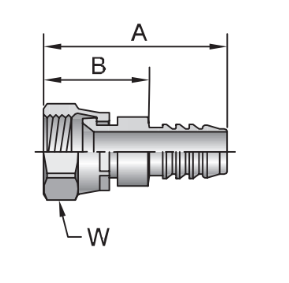

Female JIC 37° – Swivel | Hydraulic Suction Lines

Optimize hydraulic systems with our Female JIC 37° – Swivel. Precision-designed for SAE100R4 hoses, ensuring easy assembly and superior gripping action. Ideal for hydraulic suction line applications.

-

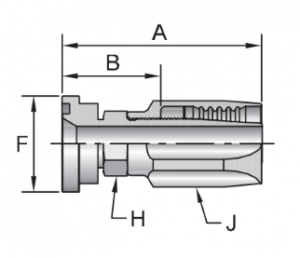

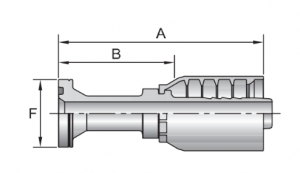

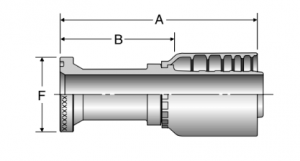

SAE Code 61 Flange Head | Field Attachable Design

Field attachable for quick and tool-free assembly with SAE Code 61 Flange Head. Zinc dichromate plated and compatible with various hoses. Durable steel construction.

-

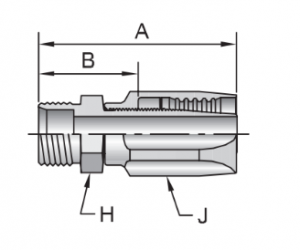

Male SAE Compression Seat | Diverse Markets / Imperial HEX Design

Male SAE Compression Seat- field assembly with versatile applications in transportation, military, agriculture, and more.

-

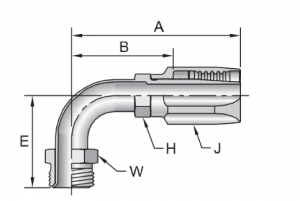

Male Inverted SAE 45° – Swivel – 90° Elbow | Swivel Feature / No-Skive Technology

Efficient Male Inverted SAE 45° – Swivel – 90° Elbow – quick hose assemblies on-site and no special tools needed. Enhances convenience with No-Skive technology.

-

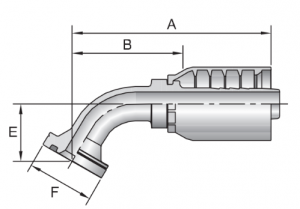

SAE Code 62 Flange Head – 60° Elbow | Metric Hex Design

High-pressure, cost-effective fittings for efficient and safe hydraulic applications with our SAE Code 62 Flange Head – 60° Elbow. Versatile in diverse industries.

-

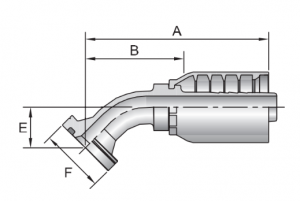

SAE Code 62 Flange Head – 45° Elbow | Crimped Connection

Explore specifications on SAE Code 62 Flange Head – 45° Elbow! Crimp design, durable for -40 °C to +105 °C. Optimal fit for fluid systems.

-

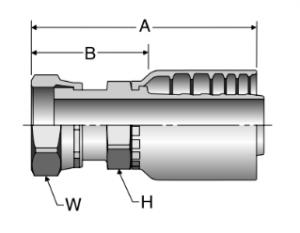

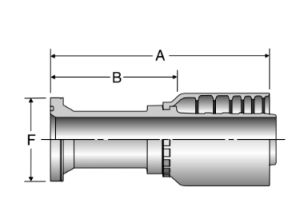

SAE Code 62 Flange Head | Thread Versatility

Choose carbon steel, 304, or 316 with metric, US, Imperial threads. NO-SKIVE design SAE Code 62 Flange Head for cost-effective hose assembly with SAE100 R13/15.

-

Female Seal-Lok – Swivel – Long | Versatile Configuration

Efficient Female Seal-Lok – Swivel – Long hydraulic fittings. Easy push-on, stainless steel option. Reduce complexity, enhance performance.

-

Caterpillar® Flange Head | Dual Pressure Ratings

Versatile Caterpillar® Flange Head for fluid power systems worldwide. Code 61 and Code 62 options, interchangeable with SAE standards. Robust design, ideal for pumps and motors.

-

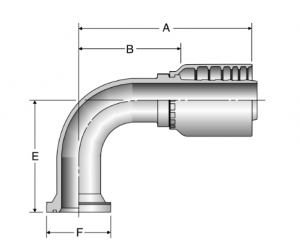

SAE Code 62 Flange Head – 90° Elbow | Chromium-6 Free Plating / Optimal Design

SAE Code 62 Flange Head – 90° Elbow for swift, No-Skive assembly. Chromium-6 free with P35 hose compatibility. Reliable and durable fitting.

-

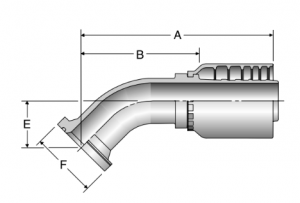

SAE Code 62 Flange Head – 45° Elbow | No-Skive Technology

Chromium-6 free SAE Code 62 Flange Head – 45° Elbow. Quick, No-Skive assembly for lasting hose connections. Ideal with P35 hose.

-

SAE Code 62 Flange Head | Chromium-6 Free Plating

SAE Code 62 Flange Head – 90° Elbow for swift, No-Skive assembly. Chromium-6 free with P35 hose compatibility. Reliable and durable fitting.